CNC Machining Industries We Serve

CNC machining supports a wide range of industries that demand precision, reliability, and fast production turnaround.

At HRCCNC, we deliver high-accuracy components for automotive, aerospace, medical, and consumer electronics applications.

Discover the industries we serve and explore examples of the parts we have manufactured.

Our CNC Machining Industries

We specialize in precision CNC machining for four key sectors, delivering high-tolerance components that meet stringent industry standards.

Automotive Industry

The automotive industry demands reliable, high-precision components that support vehicle performance, durability, and safety. CNC machining plays a vital role in producing parts with consistent tolerance control, excellent fatigue resistance, and stable quality across prototypes and mass production.

Tight dimensional accuracy for powertrain and chassis parts

Heat-resistant and corrosion-resistant materials

Rapid prototyping for design validation

Consistent quality for long-term mass production

Our Support:

HRCCNC provides flexible machining solutions for shift knobs, engines, drivetrain systems, lighting structures, customized brackets, and more.

Aerospace Industry

Aerospace applications require ultra-high precision and full compliance with strict industry standards. Components must stay lightweight while maintaining structural integrity in extreme temperatures, pressure, and vibration.

Superior precision for mission-critical parts

Lightweight metals such as aluminum, titanium, and magnesium

Complex geometries for sensor and structural assemblies

Traceability and stable machining quality

Our Support:

HRCCNC delivers reliable machining for housings, fixtures, fluid system components, and structural parts used in aerospace applications.

Medical Industry

Medical components must meet the highest standards of safety, hygiene, and biocompatibility. CNC machining enables doctors and OEMs to obtain perfectly finished parts that work reliably inside medical devices or operating environments.

Extremely smooth surface finishes

Biocompatible materials such as titanium and stainless steel

Small-batch customization and rapid prototyping

High consistency for repeatable performance

Our Support:

HRCCNC manufactures components for surgical tools, medical device frames, implants, and precision instrument parts.

Consumer Electronics Industry

The consumer electronics industry moves fast, requiring high-precision parts that achieve both functional performance and premium appearance. CNC machining is ideal for creating compact components with smooth surfaces, consistent dimensions, and excellent structural stability for modern devices.

High accuracy for thin-wall and compact components

Premium cosmetic finishes such as anodizing or polishing

Reliable dimensional consistency for large production runs

Fast prototyping to support rapid product launches

Our Support:

HRCCNC provides precision machining for casings, device frames, camera cages, internal metal structures, thermal management parts, and customized aluminum accessories used across smartphones, audio equipment, smart devices, and wearables.

Automotive Industry CNC Machined Parts

Discover precision-machined components used across cars and motorcycles, including gear shift parts, motorcycle hardware, aluminum conductors for custom car audio systems, and control knob rings. These examples highlight HRCCNC’s ability to deliver durable and high-accuracy parts for automotive applications.

Aerospace CNC Machined Components

Explore machined parts engineered for high strength, lightweight performance, and strict tolerance requirements. These components demonstrate our capability to support aerospace structures, sensor housings, and functional assemblies.

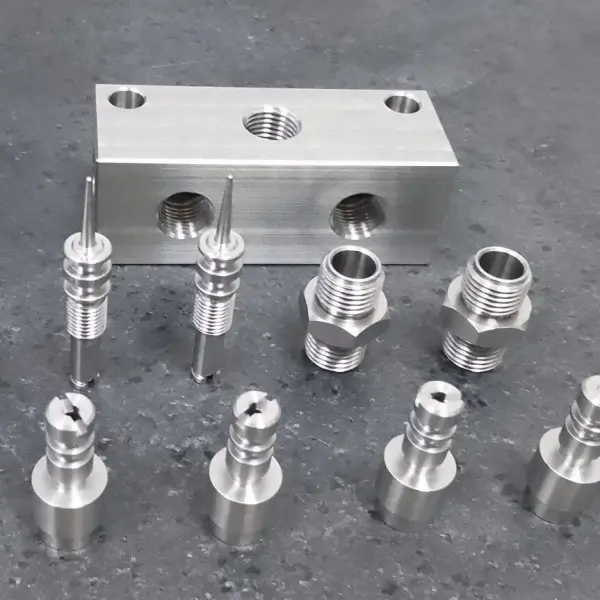

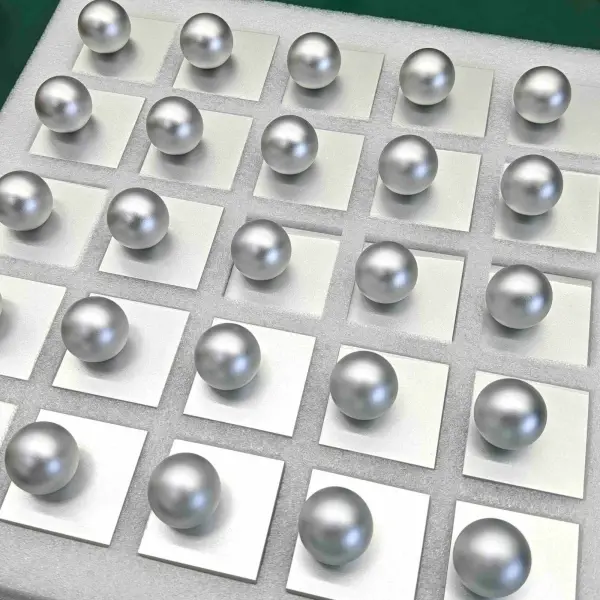

Medical Device CNC Machining Examples

View precision-engineered medical components with smooth surfaces and biocompatible materials. These examples reflect our experience in producing surgical tools, device frames, and high-accuracy instrument parts.

Consumer Electronics CNC Machined Parts Showcase

Explore a selection of finely machined components used in everyday consumer products. These examples include brass pepper grinder parts, coffee machine grinder burrs, smartphone camera cages, and aluminum coffee cup.

Additional Industries Supported by Our CNC Machining Services

Beyond automotive, aerospace, medical, and consumer electronics, HRCCNC also provides precision machining solutions for many other sectors.

- Agriculture Industry

The agriculture sector relies on durable, high-strength metal components that can withstand constant vibration, outdoor exposure, and heavy workloads. CNC machining helps produce robust and long-lasting parts used in farming machinery and irrigation systems.

- Tractor mounting brackets

- Stainless steel hydraulic fittings

- Gear housings for irrigation pumps

- Precision bushings for harvesting equipment

- Renewable Energy Industry

Renewable energy systems require lightweight, corrosion-resistant, and highly precise components to ensure safe and efficient operation. CNC machining supports solar, wind, and battery technologies with reliable and complex metal parts.

- Wind turbine sensor housings

- Battery pack heat-dissipation plates

- Aluminum solar panel mounting clamps

- Motor shafts for energy storage systems

- Industrial Automation & Robotics

Automation and robotics rely on components with tight tolerances, smooth movement, and excellent strength-to-weight ratio. CNC machining enables fast production of custom robot fixtures, actuators, and structural parts.

- Linear actuator housings

- Precision servo motor mounts

- Robot arm joints and couplings

- Aluminum automation brackets

- Industrial Design & Prototyping

Industrial designers need fast, accurate prototypes to validate product shapes, functions, and assembly performance. CNC machining allows designers to iterate quickly with production-grade materials and high-quality surface finishes.

- Prototype enclosures

- Ergonomic handle models

- Engraved metal logos or nameplates

- Concept models for consumer products

- Marine & Shipbuilding Industry

The marine industry requires corrosion-resistant and high-strength components that perform reliably in harsh and changing environments. CNC machining supports boats, underwater devices, and navigation systems with precise and durable parts designed to handle saltwater exposure, heavy loads, and continuous vibration.

- Brass marine valve bodies

- Stainless steel propeller hubs

- Corrosion-resistant clamps and brackets

- Aluminum navigation instrument mounts

- Semiconductor Industry

The semiconductor sector requires ultra-precise and highly stable components used in fabrication tools, testing equipment, and clean-room systems. CNC machining delivers tight tolerances, clean surface finishes, and reliable performance for parts that must withstand vacuum environments, chemicals, and temperature changes.

- Wafer handling brackets

- Tooling and fixture plates

- Vacuum chamber components

- Precision housings for testing devices

FAQs About Industry

What industries commonly use CNC machining services?

CNC machining is widely used in automotive, aerospace, medical, consumer electronics, agriculture, renewable energy, industrial design, and general manufacturing sectors.

How does CNC machining support the agriculture industry?

Agricultural equipment requires durable, wear-resistant metal components. CNC machining ensures strong, precise parts for tractors, harvesting tools, irrigation systems, and machinery attachments.

Why is CNC machining important for the renewable energy sector?

Wind, solar, and battery systems rely on high-accuracy housings, brackets, connectors, and structural components. CNC machining offers tight tolerances and stable quality for these critical applications.

How do industrial designers benefit from CNC machining?

Industrial designers use CNC machining to quickly turn concepts into functional prototypes. This process delivers accurate dimensions, smooth finishes, and fast turnaround for design validation.

Can CNC machining handle complex geometries for emerging industries?

Yes. CNC machining is ideal for complex shapes found in robotics, automation equipment, smart devices, and custom consumer products. Multi-axis machining enables advanced part designs.

What materials can CNC machining support across different industries?

HRCCNC works with aluminum, stainless steel, brass, copper, titanium, engineering plastics, and more. This wide selection supports diverse industrial needs, from lightweight aerospace parts to durable agricultural components.

Request a Free Quote

Upload your CAD files or part drawings and receive an accurate quotation within 24 hours. Our experts will analyze your design and provide cost-effective suggestions to enhance manufacturability and reduce lead time.

Design Consultation Services

Need help refining your design? Our experienced engineers offer DFM (Design for Manufacturing) support to ensure your parts are optimized for CNC machining, reducing unnecessary costs and avoiding machining challenges.

Lead Time & Shipping Information

We guarantee fast turnaround times for prototypes (as quick as 3 days) and reliable shipping worldwide. All parts are securely packaged and tracked to ensure safe delivery to your location.

Email: Info@hrccnc.com

Phone: +86 17318068324

Our support team is available to assist you with material selection, tolerance requirements, and finishing options.