Custom Products Services

At HRC, we specialize in manufacturing high-quality components across multiple materials, including aluminum, steel, plastics, and brass. Whether you need CNC machining, sheet metal fabrication, welding, or laser cutting, we provide consistent quality, fast production, and reliable global delivery for every project—from prototyping to mass production.

Our Products

At HRC, we provide a comprehensive range of CNC-machined products across four major material categories—Aluminum, Steel, Plastic, and Brass.

CNC Aluminum Parts

Lightweight yet strong, with outstanding conductivity and corrosion resistance. Suitable for aerospace structures, consumer electronics housings, automotive brackets, frames, and decorative components where precision and aesthetics matter.

CNC Stainless Steel Parts

Known for high hardness, wear resistance, and excellent corrosion performance. Ideal for medical instruments, food machinery, chemical equipment, precision shafts, mechanical fasteners, and premium-grade hardware.

CNC Brass Parts

Featuring exceptional machinability, stable mechanical properties, conductivity, and corrosion resistance. Widely used in valve fittings, connectors, electrical terminals, decorative components, instrumentation parts, and precision gears.

CNC Plastic Parts

Capable of processing POM, Nylon, PEEK, ABS, PMMA, PC, HDPE, and other engineering polymers. Suitable for applications requiring insulation, lightweight structures, low friction, chemical resistance, or complex functional geometry.

Manufacturing Capabilities

Our factory is equipped with advanced CNC machining centers, turning machines, automatic lathes, 4-axis and 5-axis machines, and precision inspection tools. From rapid prototyping to mass production, we ensure stable, accurate, and repeatable machining quality regardless of material type.

Precision Machining Centers

We operate an advanced machining fleet capable of handling both simple and highly complex part geometries:

- Five-axis CNC machining centers: Capable of high-precision machining of complex spatial surfaces.

- High-speed CNC milling machines: Spindle speeds up to 20,000 RPM, suitable for high surface finish requirements.

- Precision CNC lathes: Repeat positioning accuracy ±0.002mm, suitable for high-precision rotary parts.

- Turn-mill centers: Complete multiple processes in one setup, improving efficiency and accuracy.

- Maximum machining size: 1200×800×600mm.

- Highest machining accuracy: Up to IT4-IT6 grade.

Sheet Metal Fabrication

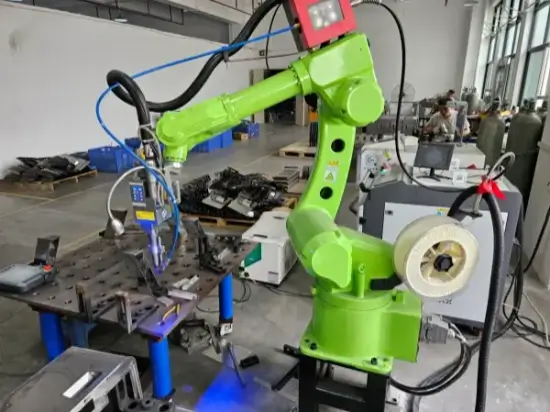

Our sheet metal fabrication department is equipped with a complete set of modern equipment, providing one-stop sheet metal solutions from laser cutting, CNC punching, bending to welding assembly. Advanced laser cutting technology allows for cutting thicknesses up to 25mm with accuracy up to ±0.1mm. Robotic welding systems ensure stable and reliable weld quality, meeting the strength requirements of various structural parts.

- Laser cutting machine: 6000W power, maximum cutting thickness 25mm, positioning accuracy ±0.05mm.

- CNC punch press: 60-ton capacity, maximum processing size 2000×1000mm.

- Bending machine: CNC bending accuracy ±0.1°, maximum pressure 300 tons.

- Welding robots: 6-axis welding robots equipped with MIG/TIG welding systems.

- Surface treatment line: Full range of surface treatment capabilities including sandblasting, powder coating, electrophoresis, anodizing, etc.

- Maximum processing size: 3000×1500mm.

Quality Assurance

Comprehensive Quality Control System

We have established a full-process quality control system from raw material receipt to finished product shipment, ensuring every step meets the highest quality standards. Equipped with internationally advanced testing equipment and a professional quality inspection team, we provide reliable quality assurance for our clients.

Process Control (IPQC)

Implements full-process IPQC inspection, including: raw material inspection, first article inspection, in-process inspection, and final inspection. Our quality control engineers conduct real-time monitoring during production to ensure process stability, promptly identifying and correcting deviations.

Testing Equipment

- Coordinate Measuring Machine (CMM): ZEISS CONTURA G2, measurement accuracy 0.9μm+L/350.

- X-ray inspector: Detects internal defects and structural integrity of parts.

- Spectrometer: Precisely analyzes material chemical composition to ensure material conformity.

- Optical Comparator: Measures two-dimensional dimensions and geometric shapes.

- Roughness Profilometer: Measures surface roughness and profile accuracy.

- Hardness Testers: Capable of Rockwell, Vickers, and Brinell hardness testing.

Certification and Reporting

Strictly adheres to the ISO 9001:2015 Quality Management System and is certified to BSCI/ROHS for the industry. Can provide complete inspection reports with shipments, including: Material Certificate, Mechanical Performance Test Report, Full Dimensional Inspection Report (FAI), First Article Inspection Report, etc.

Delivery Capabilities

We understand the importance of on-time delivery for client projects. Through scientific production management and supply chain optimization, we ensure every order is delivered on time, to specification, and in full.

Flexible Production Capacity:

Rapid Prototyping Service: Complete simple part prototyping within 72 hours.

Small-batch Trial Production: Supports pilot runs of 50-500 pieces to validate process feasibility.

Large-scale Mass Production: Monthly capacity exceeding 500,000 pieces to meet high-volume order demands.

Mixed-line Production: Supports flexible switching of different products on the same production line.

Logistics Solutions

Global Logistics Solutions

We have established long-term strategic partnerships with major global logistics providers, offering clients efficient, safe, and cost-effective transportation solutions to ensure goods are delivered worldwide on time and intact.

International Express Services

- DHL: Global network coverage, door-to-door express service, suitable for samples and urgent shipments.

- FedEx: International Priority service, 1-3 business days delivery to major countries.

- UPS: Worldwide Express service, providing real-time tracking and proof of delivery.

- Dedicated Express Lines: More cost-effective express services for specific countries.

Air Freight Services

- Door-to-Door Air Freight: Full agency service, clients only need to provide delivery information.

- Economy Air Freight: Balances speed and cost, suitable for small to medium volume shipments.

- Commercial Flights: Utilizes belly space on commercial flights for stable transit times.

- Charter Services: Provides dedicated charter solutions for large-volume urgent shipments.

Sea Freight Services

- Full Container Load (FCL): 20ft/40ft/40ft High Cube containers, suitable for large-volume shipments.

- Less than Container Load (LCL): Cost-effective, suitable for small to medium volume shipments.

- Main Shipping Routes: Covers major ports in Europe, North America, Southeast Asia, the Middle East, Australia, etc.

- One-stop Service: Includes booking, customs declaration, insurance, customs clearance, and door delivery.

Rail Transport

- China-Europe Railway Express: Stable land transport channel from China to Europe, transit time approx. 18-22 days.

- Central Asia Railway: Railway network connecting China with five Central Asian countries.

- Environmental Advantage: 95% less carbon emissions compared to air freight, 50% time savings compared to sea freight.

- High Safety: Full GPS tracking, stable transport environment, low cargo damage rate.

Value-added Services

- Warehousing Services: Provides short-term and medium-to-long-term warehousing solutions.

- Sorting & Packaging: Product sorting and customized packaging according to client requirements.

- Customs Clearance Service: Professional customs clearance team ensures smooth cargo clearance.

- Insurance Services: Provides comprehensive cargo transportation insurance to protect client interests.

Customer Reviews

We are trusted by clients across the USA, Europe, and Asia, serving industries such as automotive, robotics, medical devices, consumer electronics, machinery, and custom product development. Our long-term partners recognize our reliability, consistent quality, and fast response.

We have cooperated with HRC for over five years. Their engineering team demonstrates excellent attention to detail, and their responsiveness is outstanding. Product quality is consistently stable — a truly reliable partner in our supply chain.

——Arnold Harris,United States

An outstanding supplier. The quality of the metal parts is simply flawless, with perfect finishing and remarkable attention to detail. Customer service has been excellent, always responsive and supportive. Shipping was fast and the packaging carefully prepared, showing great attention throughout the entire process. In short, a 10 out of 10 experience in every aspect: quality, service, detail, and professionalism. Without a doubt, a trusted partner we will be happy to work with again.

——Javier De Andres Garcia,Spain

Excellent experience! The CNC machined parts arrived exactly to spec with a great finish. Seller had a good understanding of my requirements. Highly recommend!

——Audrey Castillo,United States

Related Articles

Stay updated with our latest industry insights, machining guides, material comparisons, and manufacturing tips.

Surface Finish vs Surface Roughness: How Do the Two Differ?

Even the slightest alteration in the surface finish specs can turn your high-end CNC parts worthless. Precision machining of parts

Polypropylene (PP) Melting Point: Temperature, Range, and Uses

Polypropylene (PP) is one of the most used thermoplastics. It’s featured in everything from packaging films and household goods to

Everything About Blackening Coating: What is Black Oxide Coating?

Even precision-machined components, by the time they reach the client, develop surface rust. The so-called ‘negligible minor issue’ eventually starts

Melting Point of Plastic: At What Temperature Does Plastic Melt?

Plastic is literally everywhere, from food packaging to technological power. Many applications require direct or indirect exposure to heat. That’s

Industries We Serve

We serve a wide variety of industries, including automotive, robotics, electronics, aerospace, medical devices, home appliances, industrial machinery, and consumer products. From precision metal components to custom plastic parts, our fabrication services deliver the flexibility and performance needed across nearly every manufacturing sector.

- Automotive Industry

provide finishes that withstand harsh environments, temperature fluctuations, and exposure to chemicals. Our solutions enhance both functionality and aesthetics.

- Engine components

- Transmission parts

- Brake system components

- Interior and exterior trim

- Medical Devices

We consistently provide premium aesthetically pleasing, durable finishes that enhance overall product appeal while effectively protecting critical components.

- Surgical instruments

- Implantable devices

- Diagnostic equipment

- Prosthetics and orthotics

- Aerospace & Defense

Our finishes meet rigorous standards for extreme environments, corrosion resistance, and durability.

- Aircraft structural components

- Engine turbine parts

- Avionics enclosures

- Defense system components

- Consumer Electronic

We provide aesthetically pleasing, durable finishes that enhance product appeal while protecting components.

- Smartphone and tablet enclosures

- Laptop chassis

- Wearable devices

- Audio equipment

Related Inquiries

We are always ready to answer your questions and provide professional advice.

Material Selection Consultation

Recommend the most suitable material based on your application scenario, providing material performance comparisons and technical parameters.

Process & Design

Optimization

Optimize design schemes to improve manufacturability and reduce costs, providing DFM analysis reports.

Quotation & Sampling

Process

Quickly provide accurate quotations and arrange sample production, supporting various methods such as 3D printing and CNC prototyping.

Custom Requirement Communication

Tailor special machining solutions for you, including special materials, special processes, and special surface treatments.

Are you ready to customize your product?

- Get your custom quotation and manufacturing plan today.

Click the button below to submit your project details. Our team will contact you within 24 hours with tailored solutions and pricing.

Request a Free Quote

Upload your CAD files or part drawings and receive an accurate quotation within 24 hours. Our experts will analyze your design and provide cost-effective suggestions to enhance manufacturability and reduce lead time.

Design Consultation Services

Need help refining your design? Our experienced engineers offer DFM (Design for Manufacturing) support to ensure your parts are optimized for CNC machining, reducing unnecessary costs and avoiding machining challenges.

Lead Time & Shipping Information

We guarantee fast turnaround times for prototypes (as quick as 3 days) and reliable shipping worldwide. All parts are securely packaged and tracked to ensure safe delivery to your location.

Email: Info@hrccnc.com

Phone: +86 17318068324

Our support team is available to assist you with material selection, tolerance requirements, and finishing options.

Request a Quote Now